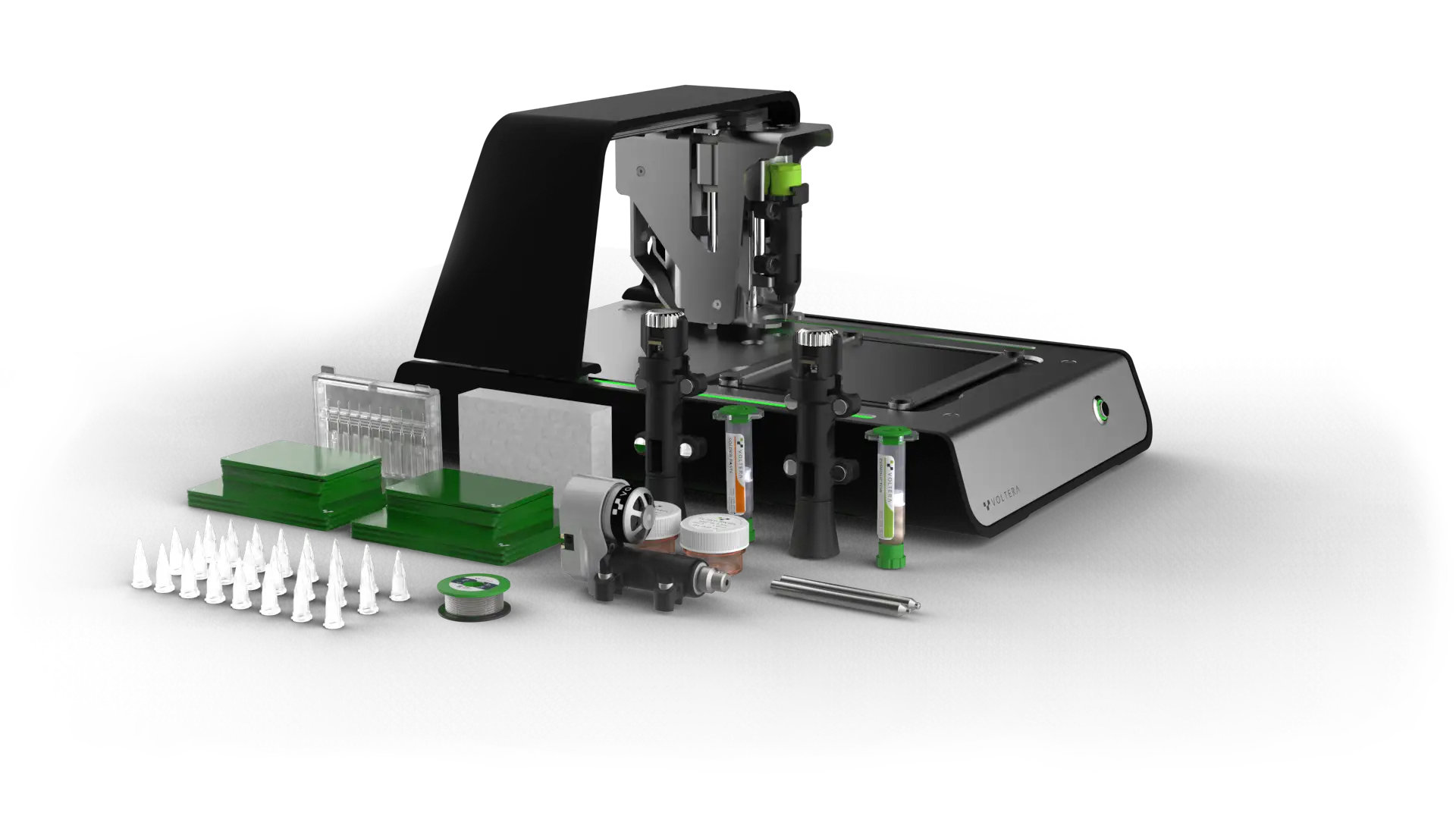

I’ve been given a Voltera machine to do some PCB prototyping at home (thanks Rob!). These are pretty amazing machines.

They use conductive silver ink to create the traces and pads. When this works it’s incredible - when it doesn’t, it’s very much like 3D printing with a lot of messing around.

Is it the end of the PCBWay+atomic14 relationship? Well, not really, there are some quite serious limitations.

There is a drill attachment for the machine and you can create vias and the equivalent of plates through holes using small rivets. But I don’t have the drill attachment and I think trying to line up the top and bottom layers would be pretty difficult.

Trace width and spacing is a minimum of 8 mil (0.2mm). For the design I did I went with 4mm to be safe.

There’s a minimum of 0.65mm pin pitch for SMT IC packages and they recommend using a minimum of 0603 passive component size.

The conductive ink bonding to the board is also not very strong, so any components that might get physical abuse can be quite fagile.

You also need to use special low temperature lead free solder paste.

But, the biggest limitation is the price! The machine costs $5000+ US and the ink and paste are both pretty expensive.

End to end the process is pretty quick, with practice you could be producing PCBs in 1-2 hours.

The process is pretty straightforward once you’ve got your PCB designed.

- Clamp the board in the machine and align the circuit with it

- Probe the height of the board to build up a height map

- Prime the conductive ink dispenser and check the calibration

- Print the circuit

- Cure the conductive ink

- Wait for the machine to cool down

- Prime the solder paste dispenser

- Dispense the paste

- Place the components - this is a manual step - no pick and place built in

- Reflow

All in all it’s a great addition to the workshop for doing quite prototypes, but it’s not going to replace having a proper PCB manufacturer.