Sometimes the correct engineering decision is to throw something away. This was not one of those times.

I’ve got an embarrassing number of microSD card adapters. They’re cheap, they come free with cards, and they tend to pile up in drawers.

So when one of them stopped working, the sensible thing would have been to bin it and grab another.

Instead, I wondered:

Can this be fixed at all? And more importantly — how do these things actually work inside?

This post accompanies the video below, where I crack open a broken microSD adapter, make things worse, and then accidentally bring it back to life.

📺 The Video

I Bodged a microSD Adapter Back to Life

The Problem: A Very Unhealthy Noise

The adapter didn’t just fail quietly — it made a horrible scratchy sound when inserting a card, and it wasn’t detected by the computer at all.

That sound turned out to be the biggest clue.

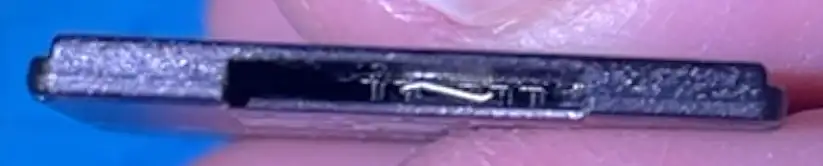

With a torch and a microscope, it was possible to look inside the end of the adapter and compare it with a known-good one.

Something was clearly out of place.

One of the spring contacts had bent sideways instead of sitting neatly at the end of the slot.

Cracking It Open (Irreversibly)

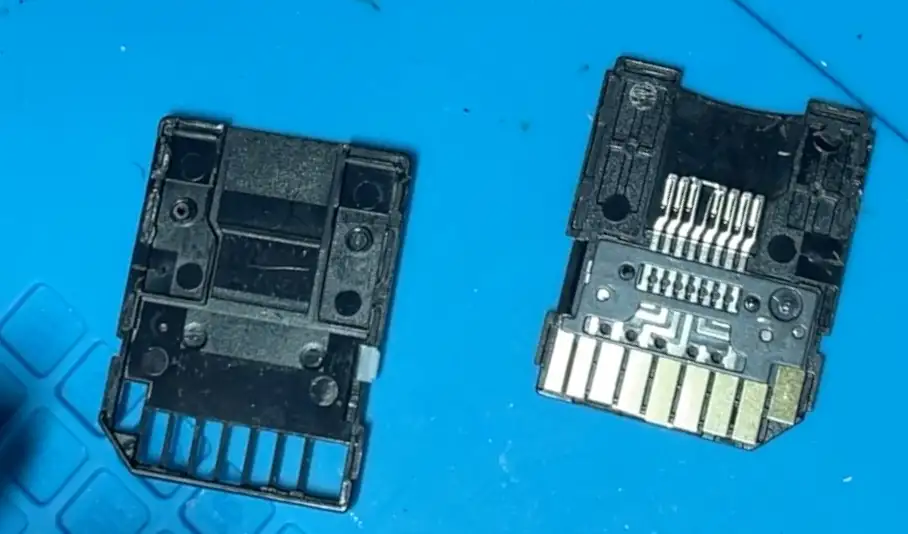

There are no screws. These adapters are glued together.

With a bit of persuasion (and a worrying crack), the case finally came apart — and the problem was immediately obvious.

One of the tiny spring contacts had been bent, and part of it had actually snapped off.

At this point, the adapter was definitely worse than when I started.

How microSD Adapters Actually Work

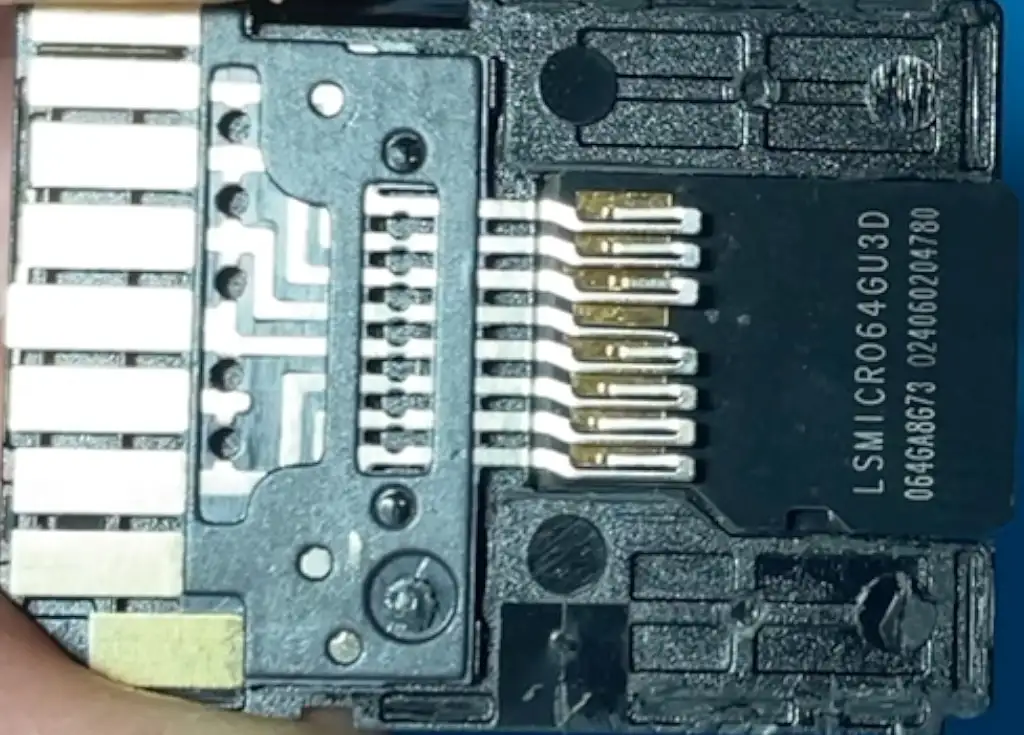

Inside, the adapter is beautifully simple:

- Each microSD pad connects to a spring contact

- The spring presses against the card when inserted

- The pressure ensures reliable electrical contact

Lose the tip of that spring, and there’s nothing left to touch the card.

Which brings us to the bodge.

The Bodge™

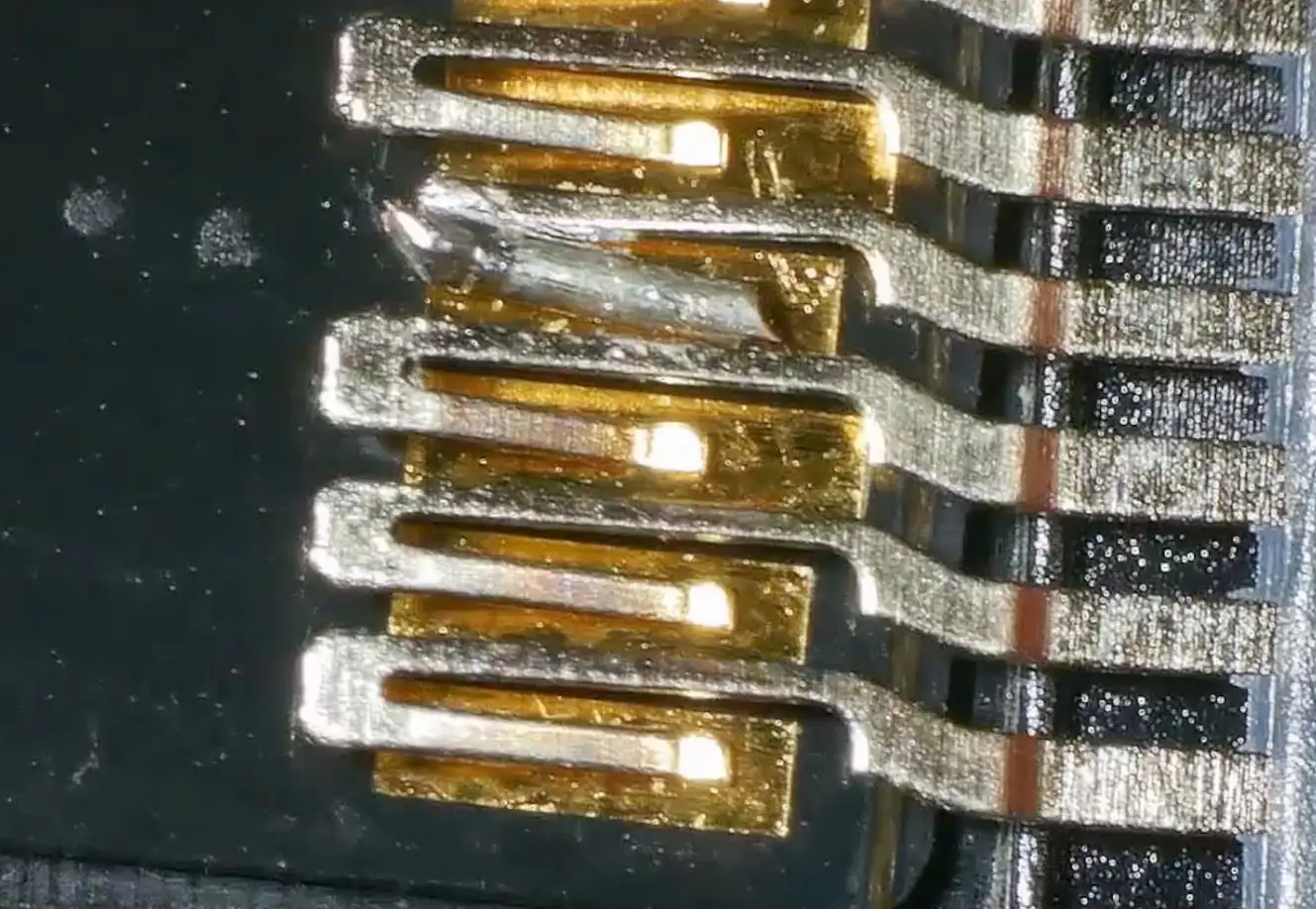

Since the original contact tip was gone forever (lost to the workshop floor), the only remaining option was… creativity.

I chopped the lead off a resistor and soldered it onto what was left of the spring contact.

This is absolutely not how this part was designed to work.

But with some careful bending, it might just make contact with the SD card again.

Continuity checks said it was connected.

No shorts between pins.

Time to test it.

Shockingly… It Worked

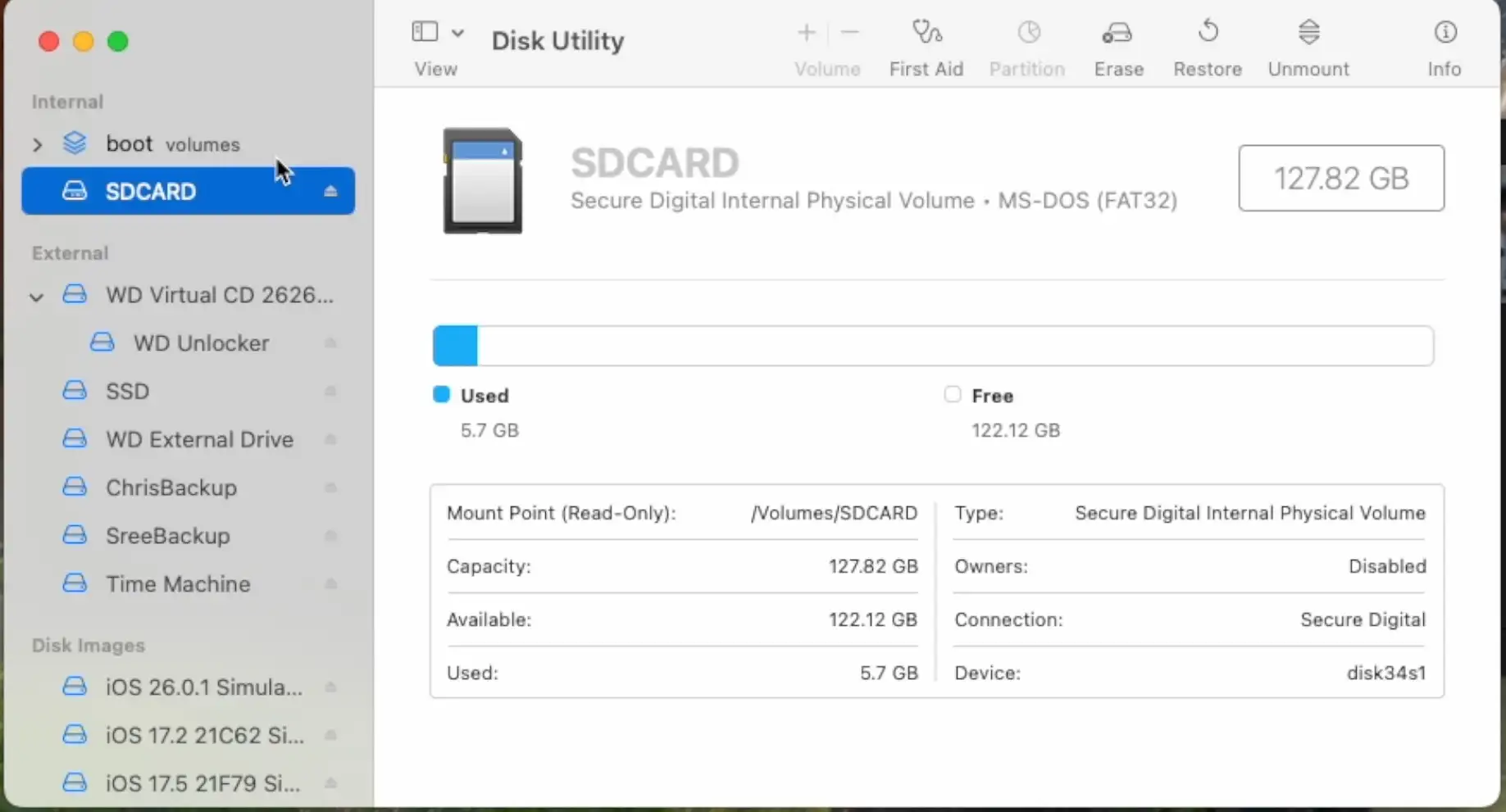

Plugged into the computer, the SD card appeared instantly.

Even Final Cut popped up asking if I wanted to import media.

Formatting, reading, writing — all working.

I was genuinely surprised.

Should You Do This?

No.

Absolutely not.

This adapter:

- Is mechanically compromised

- No longer clips together properly

- Contains a hand-soldered bit of resistor lead pretending to be a precision spring contact

I won’t be trusting it with anything important.

But as an experiment?

It was definitely interesting.